Reefer Container

We know your refrigerated cargo important to you. Whether it be perishable fruits/vegetables, frozen seafood/meat or pharmaceutical high-value cargo, our reefer experts ensure that your cargo is kept in optimal condition at all times. We know that you need reliable container that is clean, safe and provides you with precise temperature control.

ThaiReefer Group continuously invest in reefer container to ensure that we are one of the largest reefer container provider in the market.

We have 24/7 reefer technician experts who to answer your questions and service your reefer container. All of this is to safeguard your valuable cargo.

For rental and sales, we offer wide range of 10’ (3m) , 20’ (6m) , 40’ (12m) , 45’ Reefer Container.

Contact info@ThaiReefer.co.th or call us for more information.

Overview

Container Manual Download

![]() Document for Carrier Thin Line Unit

Document for Carrier Thin Line Unit

![]() Document for Carrier Prime Line Unit

Document for Carrier Prime Line Unit

![]() Refrigeration Manual for 69NT40-541-500 to 599

Refrigeration Manual for 69NT40-541-500 to 599

![]() Document for Thermoking Magnum Unit

Document for Thermoking Magnum Unit

![]() Refrigeration Manual for Thermoking Magnum Unit

Refrigeration Manual for Thermoking Magnum Unit

![]() Manual for Daikin LXE10E-A Unit

Manual for Daikin LXE10E-A Unit

![]() Technical Specifications for Carrier 69NT40-561-250 Unit

Technical Specifications for Carrier 69NT40-561-250 Unit

Reefer containers are used to handle temperature sensitive cargo. They can be used to supplement cold storage or used in intermodal transport – Sea, Rail and Road. Reefer containers are capable of controlling temperature ranges between +30 to -40 degrees Celsius. Special reefer units can regulate temperature as low as -60 degree Celsius. Reefer containers are mostly 20’ (6 meter) and 40’ (12 meter) in length. However, we offer special sizes, 8’, 10’ and 45’ according to customer’s requirements

Why ThaiReefer is the #1 choice for customers:

• Full technical service support

• Full parts support

• Mobile Reefer Technicians on 24/7 standby

• Container stock available to meet customer’s immediate demand

• Wide range of stock available

We also have other containers types available including Dry Containers, ISO Tank Containers, Flat Rack.

Contact us for more information and special rates.

Operational environment

The container is designed and manufactured for the transport of frozen, chilled and general cargo in marine, on highway and railway throughout the world. It must remain serviceable under the operating conditions encountered during each of the above mode of transport, as well as during climatic condition at temperatures of minus 40 deg.C to plus 80 deg.C without any effect on the containers strength and water-tightness.

Handling

1) Lifting, loaded or empty, at the top corner fittings vertically by means of spreaders fitted with hooks, shackles or twist-locks.

2) Lifting, loaded or empty, at the bottom corner fittings using slings with terminal fittings at any angle between vertical and 30 degrees to the horizontal.

Transportation

Road: On flat bed or skeletal chassis, secured by twist-locks or combination of twist-locks and front penetration pins to lock the two (2) bottom corner fittings.

Insulation (typical)

| Thickness | Overall Density | Core Density | |

| Base | 95 mm. | 50 kg./cu.m. | 40-47 kg./cu.m. |

| Side | 65 mm. | 45 kg./cu.m. | 35-42 kg./cu.m. |

| Roof | 90 mm. | 45 kg./cu.m. | 35-42 kg./cu.m. |

| Door | 78 mm. | 55 kg./cu.m. | 45-52 kg./cu.m. |

| Front wall | 67-85 mm. | 50 kg./cu.m. | 40-47 kg./cu.m. |

Refrigerated system

The system is designed to maintain cargo temperatures in a range from –40°C (-22°F) to +30°C (86°F).

The system is designed to operate in ambient temperatures from –30°C to +50°C

The refrigeration system is designed to operate satisfactorily under sea going and environmental conditions as specified below: Salt –laden air, sea spray and high humidity.

Vibrations: of the types encountered on ships, trucks and rail.

The equipment is designed to operate on a nominal 380 V AC / 460 V AC, 3 phase, 50/60 Hz, primary power source. Maximum current draw is 25 Amp.

An automatic system, power supply sensing and correction, is provided to ensure the correct direction of rotation for the fan motors. This is done regardless of the incoming phase sequence from the primary power supply.

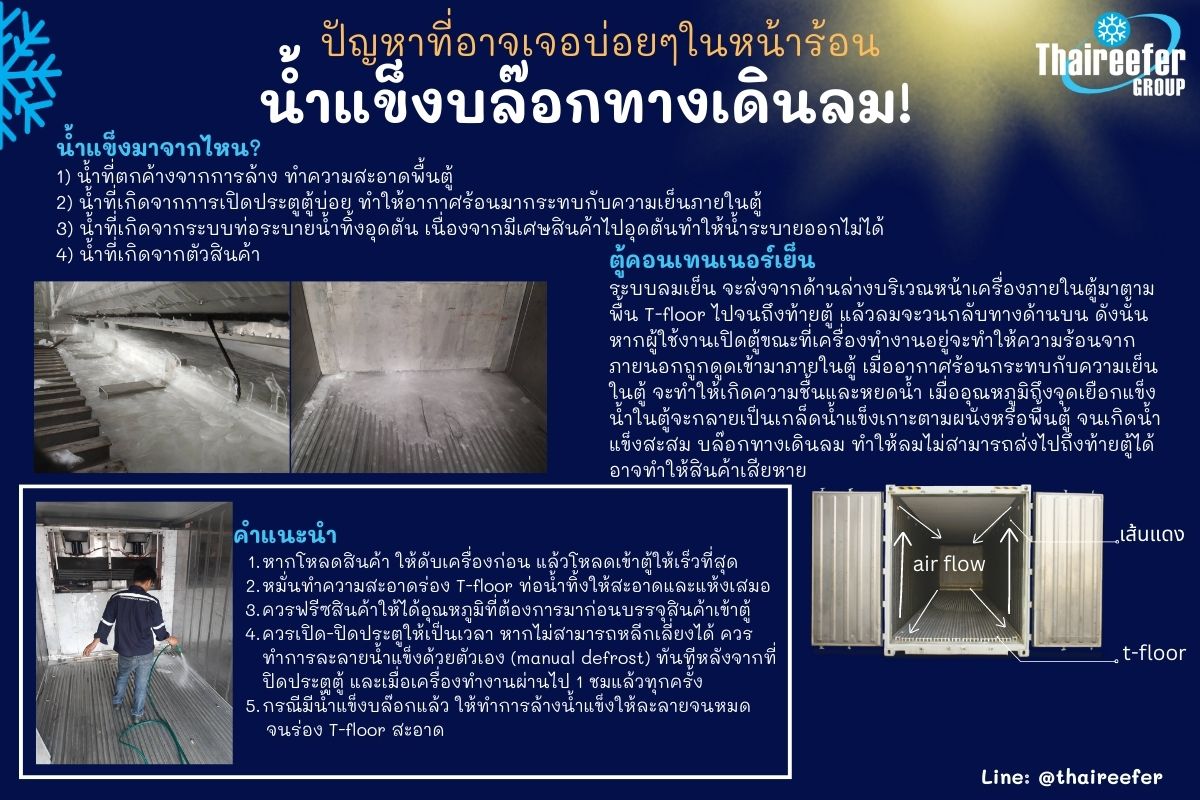

The air from the system is delivered to the bottom of the container, with return air through the top of the evaporator coil section (bottom air delivery).

The system is equipped with a data logger, incorporated in the controller.

Reefer Container Electricity Consumption

From our testing, Please see below results from using reefer container as storage. The electricity consumption varies mainly depending on frequency of door opening each day.

| KWh | THB/Month | |||

| Min | Max | Min | Max | |

| 20 Reefer Container | 2.75 | 5.5 | 7,920 | 15,840 |

| 40 Reefer Container | 3.75 | 6.5 | 9,360 | 18,720 |

*actual usage may be different

Pre Trip Inspection

Pre Trip Inspection is a standard test used to ensure that the reefer machine is without failure and can be released for next trip. Under PTI test, in the menu, it is possible to select between a normal PTI test and a Short PTI test.

How to setup Refrigerated (reefer) Containers with yourself?

6 steps to setup refrigerated container

How to set temperature on Refrigerated (reefer) Containers?

How to set temperature on Carrier Refrigerated (reefer) Containers?

How to set temperature on Daikin Refrigerated (reefer) Containers?

Step to clear Alarm List Full on Carrier ML2i & ML3

Other Container Information

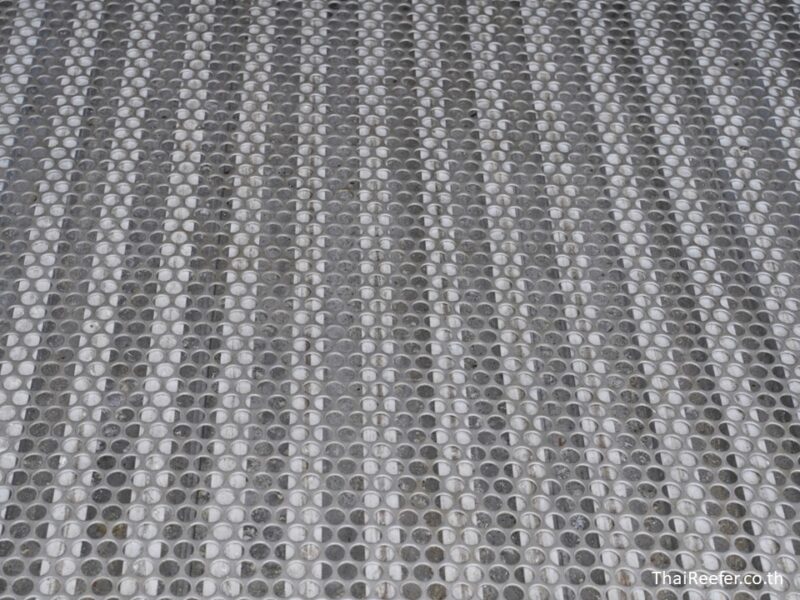

Stanless floor (Optional)